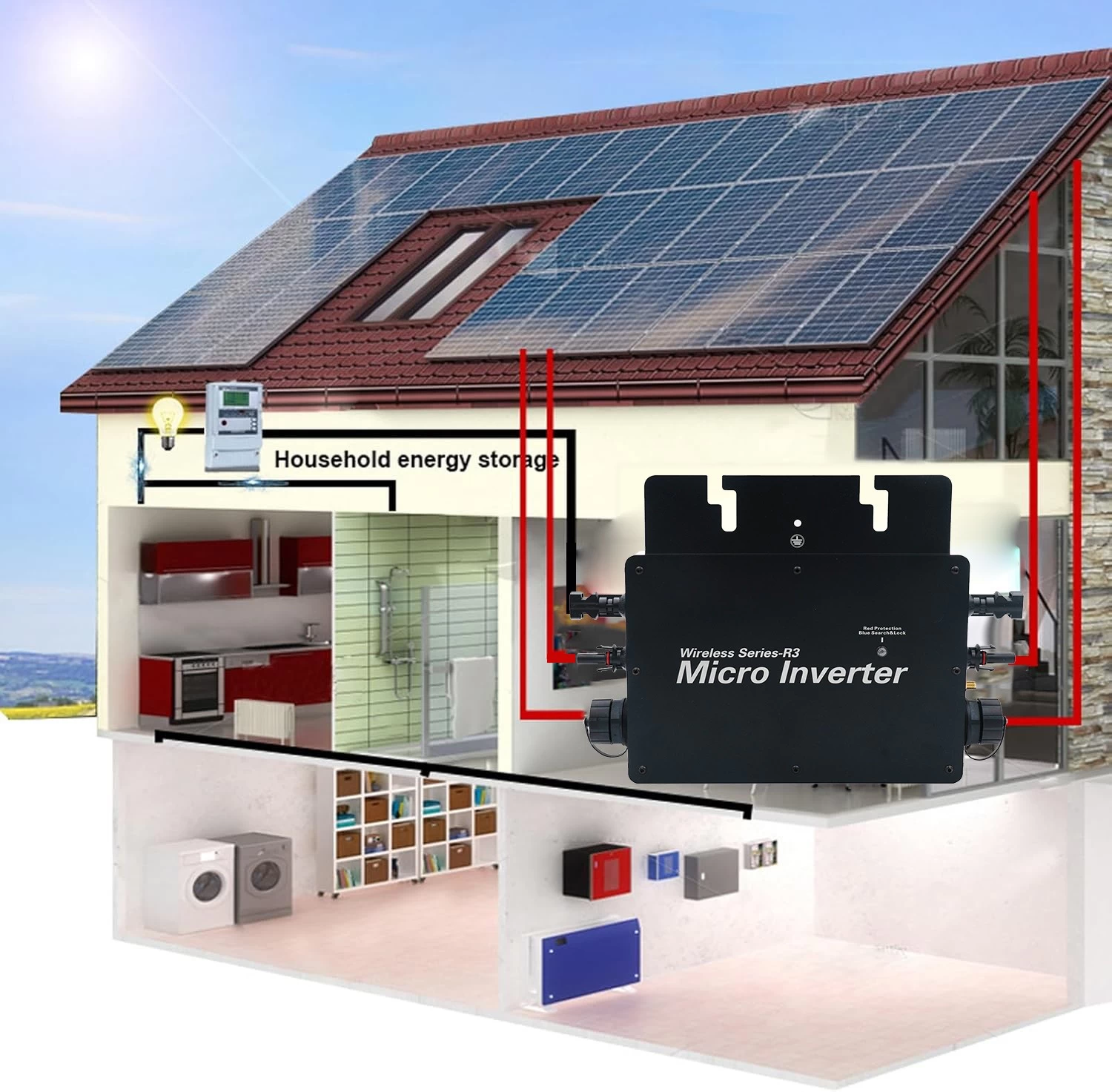

The working principle of a microinverter

The working principle of a microinverter primarily involves converting the direct current (DC) generated by photovoltaic (PV) cells into alternating current (AC) using a flyback converter. It also optimizes the power generation efficiency of each module through Maximum Power Point Tracking (MPPT) technology. The microinverter actively or passively detects information such as grid voltage and frequency to assess the grid's operating condition. When it detects grid disconnection or abnormal frequency, the microinverter quickly disconnects and stops power output to prevent the formation of an islanding effect.

A microinverter mainly consists of the following components:

1. Flyback Converter: Used to boost the DC from the PV cells to a voltage corresponding to the rectified AC output. It also isolates the PV cells from the grid through a transformer.

2. Maximum Power Point Tracking (MPPT): Optimizes the output power of each module through an independent MPPT input design, ensuring that the system's power generation is the sum of all module outputs.

3. Power Decoupling Circuit: Suppresses secondary power disturbances in the PV grid-tied system, improving system stability and longevity.

In PV systems, the application and advantages of microinverters include:

1. Overcoming the Short-Circuit Effect: By utilizing module-level MPPT technology, microinverters minimize the impact of individual modules, thereby improving overall power generation efficiency.

2. Enhancing Safety: By connecting to each module, microinverters enable individual control of each module, increasing system safety and reliability.

3. Cost Savings: Microinverters have a longer lifespan, eliminate secondary installation costs, and have lower maintenance costs, resulting in lower overall lifecycle costs.

In summary, through its unique working principle and components, the microinverter plays a crucial role in PV systems, enhancing power generation efficiency, safety, and economic benefits.